Kupari ja kullan kaivostoiminta Korkea kovuus Hyvä kulutuskestävyyspallomylly

- HY

- Kiina

- 20-45 päivää

- 50000T

Kupari ja kullan kaivostoiminta Korkea kovuus ja hyvä päällystysmateriaalipallot tuottavat pääasiassa kaivos- ja sementtiteollisuudessa erilaisia jauhamismediapalloja. Sementtitehdas, voimala, kemianteollisuus. edistyksellisen automaattisen valssauskoneen tuottamat kuumavalssattavat hiomapallot (hiomapallot 20mm-70mm) + työvoimahammeri (80mm-150mm), jossa on erityinen lämmityskäsittely ja tiukka laadunvalvonta systerm, joka tekee hiomapallomme korkean suorituskyvyn hiomapallojen raaka-aine Osto: Strateginen kumppanuus standardi terästeollisuuden kanssa ja allekirjoita pitkäaikainen sopimus (50 000 tonnia vuodessa) Osta suoraan kiinalaiselta kuuluisalta terästeollisuusyritykseltä, kuten laigang Group, HBIS, ANSTEEL, XIWANG Special steel. Meillä on erikoisosasto QC-tiimityöstä. QC-osaston johtajalla on 10 vuoden kokemus tällä alalla. Tiimi vastaa tarkastuksesta tuotannon aikana, tarkastuksen ennen toimitusta. (Taotut teräksen hiomapallot Pinnan ja ytimen kovuuskoe joka päivä ja kaikki tallennetaan ja tallennetaan asiakirjoihin)

Jinan Haoyang Casting & taonta Co, Ltdon yksi johtavista hiomakoneiden valmistajista Kiinassa. Tuotteemme on suunniteltu raaka-aineiden jauhamiseen sementtitehtaiden, energiantuotantolaitosten, malmin kaivos- ja teollisuuskäsittelylaitosten, Kiinassa sijaitsevien rakennusmateriaalitehtaat. Haoyangin teräspallojen tuotantolaitos otettiin käyttöön kesäkuussa 2008.Tällä hetkellä käsitellään jatkuvasti kasvavia kuluttajavaatimuksia hiontamateriaalien toiminnallisille ominaisuuksille, mikä vaikuttaa suoraan pallomyllyhintoihin ja laatuun, laitteiden tehokkuuteen ja yleisesti yrityksen toimintaan.

Laitos rakennettiin käyttäen edistyksellisiä laitteita. Modernien teknologioiden ja yhteistyön avulla useiden tutkimusorganisaatioiden kanssa onnistuimme saavuttamaan erittäin korkeatasoisen laadun teräspallojen jauhamisessa. Lyhyestä historiastaan huolimatta Haoyang onnistui valmistautumaan kuulamyllyjen laadukkaiden jauhemateriaalien valmistajaksi sekä pitämään asemansa sekä kotimaisilla että ulkomaisilla markkinoilla. Haoyangin tuottamien teräspallojen käyttöominaisuudet mahdollistavat hiontatarpeen huomattavan vähentämisen palloja ja voimaa, lisätä raaka-aineiden hiontapitoisuutta, vähentää tehtaan korjausten määrää ja siten lisätä niiden tuottavuutta.

Ball Mill Range

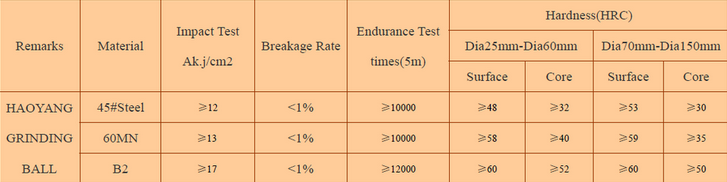

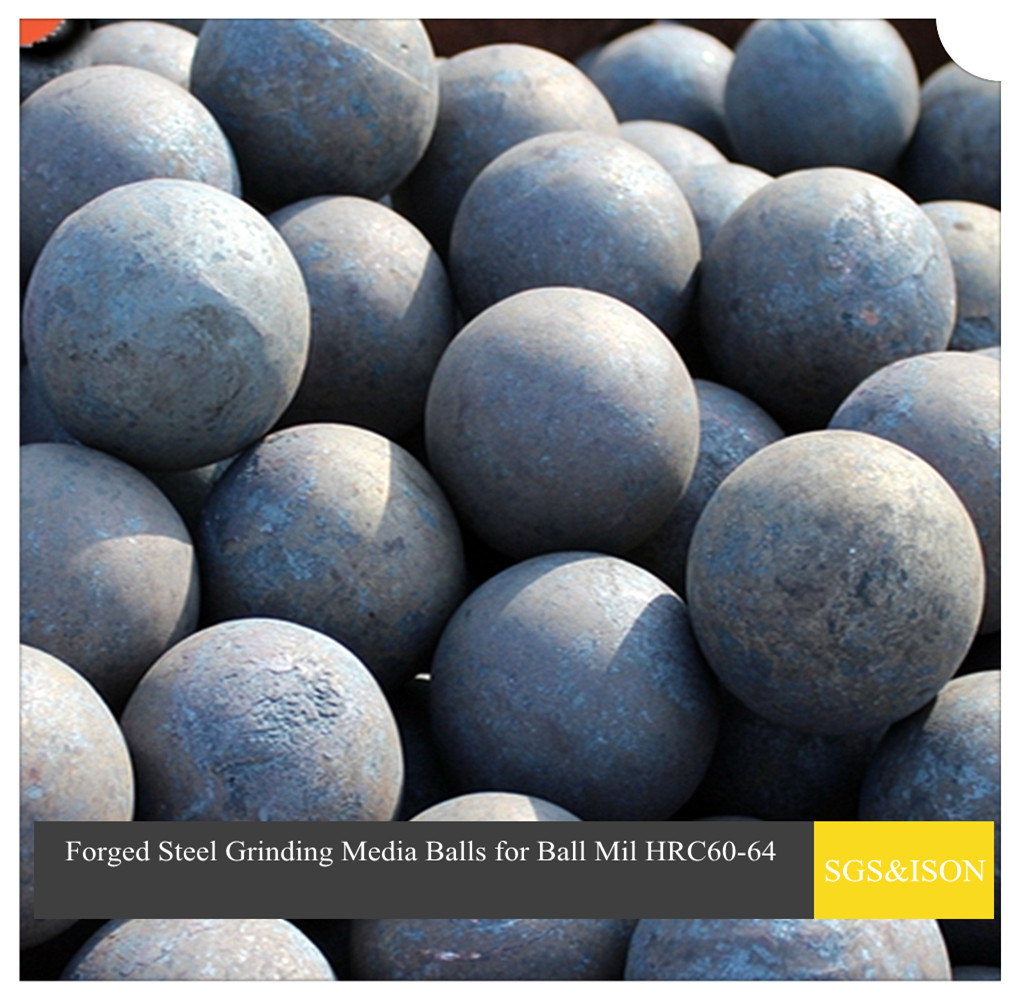

Haoyang China manufactures grinding balls to exacting internal specifications at its grinding media production facilities in Zhangqiu Shandong province China, which are strategically located to service China key mining regions. The balls are manufactured from high carbon low alloy steel bars and then forged into balls. Complete metallurgical control is maintained throughout the process, which is critical in order to obtain the optimum wear and impact resistance required for use in mineral processing operations.

Product Specifications

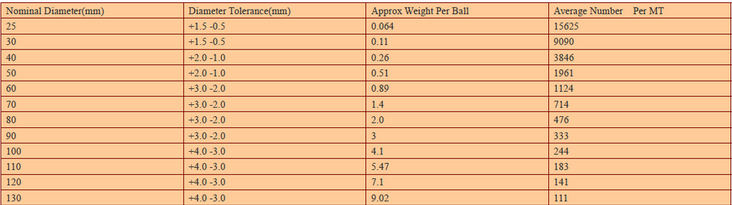

Sizes: Haoyang manufactures grinding balls in nominal sizes from Dia25mm to Dia150mm. Grinding balls in the range of Dia 50mm to 125mm in diameter are classified as medium balls and are used primarily in ball mill operations.

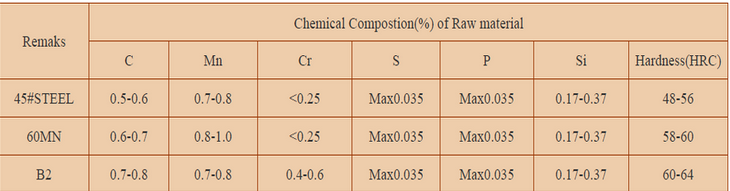

Chemistry: An individual chemical profile has been developed for each diameter ball to correspond with the requirements for heat treatment. Specific alloy additions are included to produce optimum physical properties. The chemistry of the balls is controlled through a close collaboration with our bar suppliers and robust internal quality systems.

Surface and Volumetric Hardness (Rockwell C):

The wear resistance of the balls depends on the microstructure of the steel which is altered using carefully selected heat treatment variables specifically designed for each particular alloy. The control variable for the finish product is the hardness range.

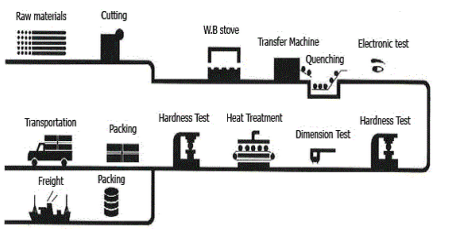

Grinding balls Production Line

Quality Production System

Grinding Media

P/O number , Batch and Date Recordings

1. Pre-production Checks : Steel bars (Diameter , Length of Cut bars, Heating Numbers signature ) Equipment includes

Air hammer Forging hammer , cooling time and Quenching time and etc..

Temperature Control :- Quenching start Temperature and Quenching End temperature . ( Produce 10 balls and then

Stop production )

2. Surface hardness measurement

Ball 1 ~~~ Ball 10 HRC Recordings

Surface Hardness Target

Materials : 60Mn

25-50mm >62 HRC

50-80 mm >60 HRC

90-125mm 56~~59 HRC

Material : B2

40-70mm >62 HRC

80-100mm 56~~60 HRC

110-140mm 52~~56 HRC

3. Core Hardness Test Store the 2 cut balls for further inspection

4. Heat Treatment before packing (Record Heat batch , Temperature)

5. Final Hardness Test before dispatch

Mark the hardness result in the grinding balls

Supply and Quality Guarantee

Long established strategic relationships with local and foreign raw material suppliers allow us to ensure all balls supplied to our customers are made from the highest quality products and meet strict specifications. This gives our customers a confidence in the quality of the product that Haoyang is able to assure.

Packing option

Bags: Balls can be supplied in woven bags , 1000kgs per bag,on the Pallets and effort in loading and unloading.

Steel Drums: grinding balls to be packed in steel drums with openable top (with threads),drums packed on pallets made of heat treated wood or plywood, two drums per pallet

Application Area

Mine

The ore grinding media usually comes out with the steel grinding ball and steel

Grinding rod. Its quality is the decisive factor affecting the operating cost of the mineral processing plant .

We could supply different steel grinding balls in line with different mines and diversified needs of the mineral processing plant. We can offer you the wear resistant steel grinding balls with the diameter ranging from 20mm to 140mm to fit for gold ore, Silver ore, cooper ore , iron ore, etc.. Those products get extensive promotion and applications in actual mining industry , and help the customers attain remarkable economic benefits by saying a lot of procurement cost and largely boosting the production output !

Cement Plant

The power consumption and steel consumption of the ball grinding mill occupy a rather high cost ratio in the production and processing process of a cement plant. The hardness , breakage rate and the corrosion resistance of the steel grinding ball affect the production cost and efficency of the ball grinding mill.

Electric Power Plant

The consumption of the steel grinding ball makes up the bulk of the operating cost in the electric power plant . It is very meaningful of how to find a way to reduce the cost and improve the efficiency .

Chemical And other Industries

We can according to the material to be groud provide the most appropriate wear resistant steel grinding balls to enhance the production efficiency of the ball grinding mill, and debase the production cost . Also availabe is the wear resistant steel grinding rod .

Why Choose Haoyang ?

Where we will buy the steel - Just directly from China Famous steel company or whose qualified distributors.

Haoyang have agent in Europe and providing grinding balls solutions for Gold mining . All the goods will be inspected in factory and then inspected in Loading

Port of china by SGS before loading on board . If unqualified , all the containers

Will be returned back to factory ! And we accept the claims caused by any problem of the steel .